PS/PW Line Heat Exchangers

Shell and U-Tube Heat Exchangers

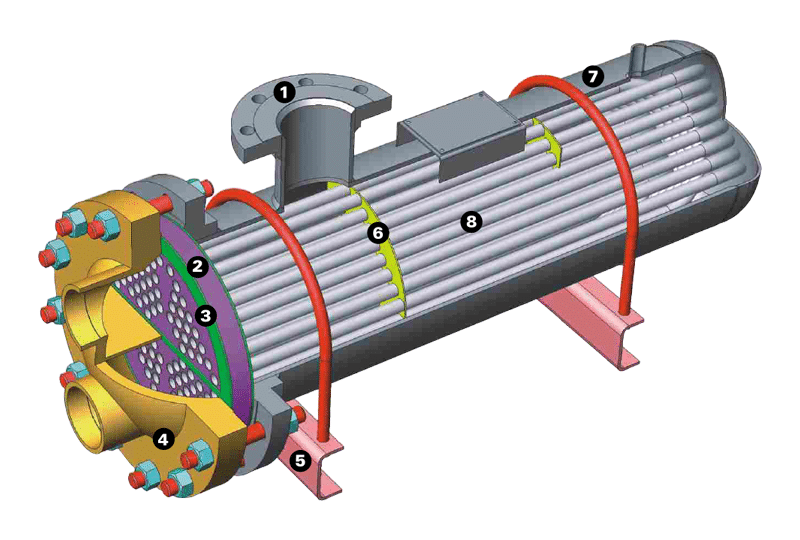

PS and PW-Type U-tube heat exchangers are designed for a wide range of liquid to liquid (PW) and steam to liquid (PS) applications.

Enhanced with stainless steel tubing in the standard construction, and available in a broad range of sizes and configurations, these PS/PW U-tube heat exchangers are designed for industrial applications with strict duties and heat transfer requirements.

The removable tube bundles make it convenient to clean and inspect these units.

We offer products of the highest quality and reliability to satisfy our customers’ most rigorous demands.

Applications

- Industrial and commercial heating and cooling

- Industrial and commercial condensers

Optional construction materials are available. A unit may be fabricated using dissimilar metals for each section. Please contact our office for details.

Maximum Working Pressure

- Up to 150 PSI (1.03 MPa)

Maximum Working Temperature

- Up to 375°F (190°C)

Standard Materials

- Stainless steel 304 tubes

- Carbon steel shell

- Carbon steel tubesheet

- Cast iron/steel head

- non-asbestos/pressed fibre gaskets

PS and PW type U-tube heat exchangers are designed for a wide range of liquid to liquid (PW) and steam to liquid (PS) applications.

Distinct Advantages

- U-tube construction.

- Units designed for liquid to liquid (PW) and steam to liquid (PS) applications.

- Available in standard 2 or 4 pass construction.

- Removable tube bundles for convenience in cleaning and inspection.

- Strong, durable construction with stainless steel tubes and rugged cast-iron or steel head in standard units. (Optional materials are available).

- U-tube and baffle arrangements designed to maximize heat transfer performance.

- Tubes expanded into stationary tubesheet allow for tube expansions and contractions, due to thermal fluctuations, without causing stresses on the joints. Welding tubes to the tubesheet is optional.

- Customization of units with higher pressures, temperature ratings, and other materials possible.