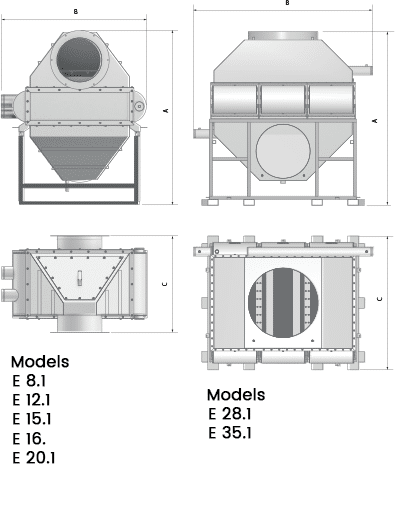

E-Line Economizers

AICs standard line of E-Line economizers is the optimal solution for boiler flue gas heat recovery.

Covering a wide range of boiler sizes, the E-Line delivers real energy and cost savings for commercial and industrial installations. In principle the E-Line economizers act as air to water heat exchangers. Flue gas, typically considered wasted heat, can be effectively cooled down and condensed through the AIC system. This cooling and condensing process releases and transfers excess energy from the flue gas to process fluids flowing through the tubes.

Typical economizer applications include

- District heating systems

- Greenhouses

- Food processing plants

- Pulp and paper mills

- Textile plants

- Dairy processing facilities

- Hospitals

- Plume abatement

Standard Materials

- Stainless Steel 304/316L

Standard Working Pressure

- Up to 160 PSI (12 bar) in Tubes (Liquid Side)

Standard Working Temperature

- Up to 375 °F (190°C) Tube Side (Liquid Side)

Stainless steel condensing secondary heat exchangers from AIC constitute an integral part of any efficiency improvement program. Typically used with hot water boilers or configured with older type of heating boilers, condensing economizers improve the overall heat recovery system and boost boiler efficiencies.

Features & Benefits

- Increased system efficiency

- Real energy and cost savings

- Converts standard boilers into condensing boilers

- Increases existing boiler efficiency by up to 20%

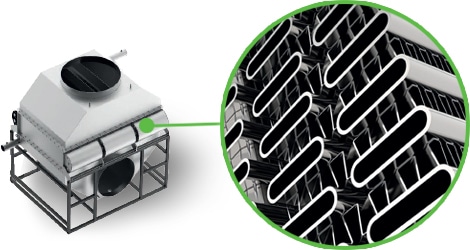

- Unique tube design for optimal thermal performance

- Easy installation, low maintenance