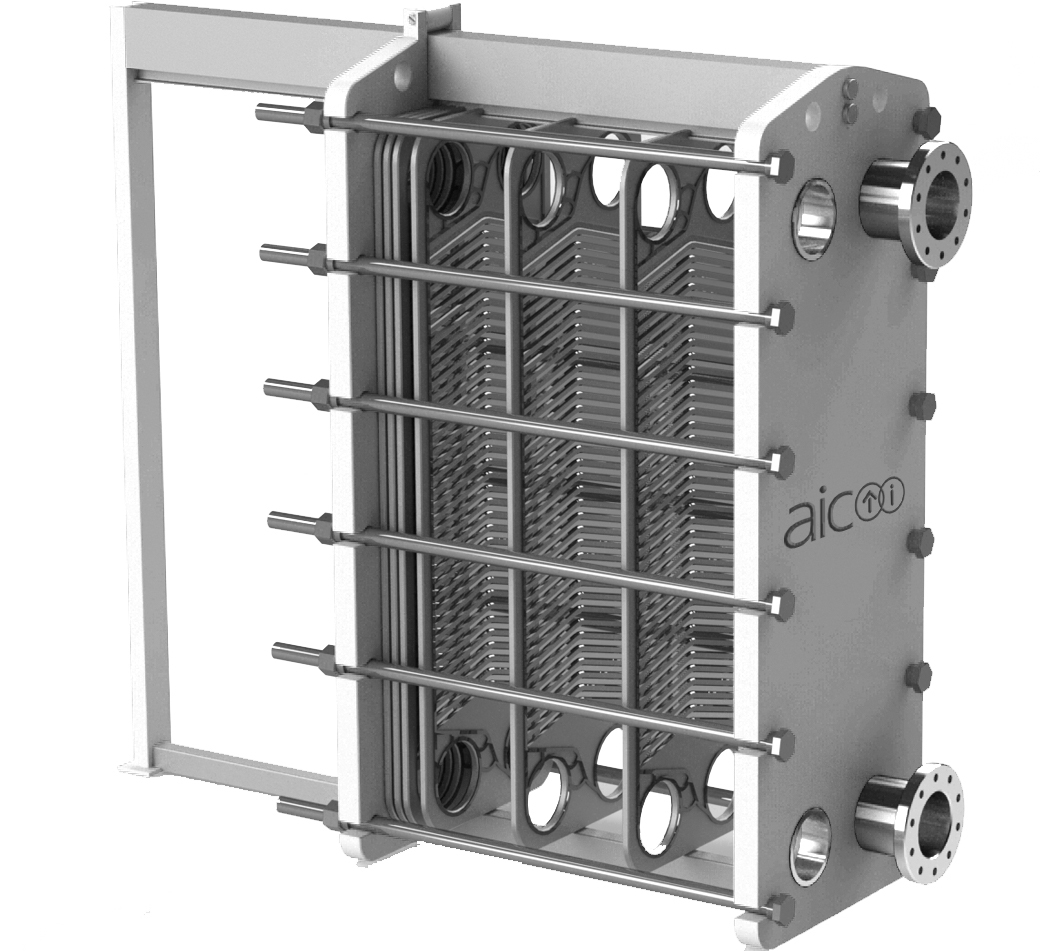

AX-Line Heat Exchangers

The bespoke AX-Line of Sanitary Plate and Frame Heat Exchangers is designed for stringent dairy, beverage, and processed food applications, complying with FDA material standards, and conforming to strict hygienic demands of the food and dairy industry.

A blend of performance and refined engineering details, the AX gasketed plate heat exchanger technology promotes optimal time-temperature heat treatments and consistent control throughout each heating and cooling process, resulting in quality product outputs.

Applications

- Milk and cheese pasteurization

- Beverage and energy drink and juice pasteurization

- CIP heating

- Bottled water treatment

- RO water

- Beer wort heating and beer cooling

- Soups, sauces and starch heating

Standard Materials

- Heating Plates : SS304 , SS316 , Titanium, SMO , Hastelloy

- Frame : Cladded or Stainless Steel

- Gaskets : EPDM-HT, NBR-HT, Viton

Standard Working Parameters

- Up to 363 PSI (25 bar)

- -20°C to 180°C (-4°F to 356°F)

Design Options

Double Wall Plate System

- Minimizes risk of fluid cross-contamination.

- Two stainless steel walls within a combined plate, with an air gap in between, separate the fluid streams. In the event of a leak, the affected fluid will flow into the air gap and escape out of the heat exchanger, enabling visual detection of the leak.

Multi-Section Design

- AX-Line sanitary gasketed plate heat exchangers are available as multi-section solutions – multiple heat exchangers combined into a single installation, divided by intermediate frames.

Features and Benefits

- Accessible construction design for quick and trouble-free inspection, maintenance, and cleaning, including cleaning in place (CIP).

- Sturdy nylon rollers make the movable cover slide open effortlessly, and locking bushings with ball bearings allow it to be closed tightly again.

- Connections from DN25 to DN800 (1″ to 32″).

- Plate heights up to 3.5 m (11.5 ft).

- Flow rates up to 1,600 m3/h (7,045 gpm).

- Regenerative pasteurizers recycle up to 95% of the energy.