L-Line Brazed Plate Heat Exchangers

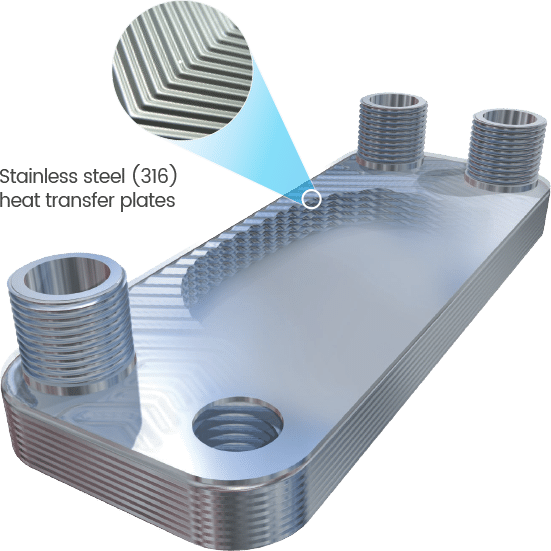

Brazed plate heat exchangers consist of stainless steel plate plates, which have embossed chevron patterns. The plates are turned 180° to each other, causing the plate ridges to intersect, and creating a lattice of intersecting channels. The fluids can flow in counter-current or co-current way.

Special corrugation patterns promote high turbulence flow. Turbulence dramatically improves heat transfer rates and reduces the amount of deposits inside the unit.

Applications

- Condensers and evaporators in refrigeration systems

- Oil coolers

- Close approach fluid-to-fluid heat transfer

- Industrial process heat recovery

- Solar and geothermal heating

- Hydronic heating and cooling

- District heating and cooling

- Gas cooling

Standard Materials

- Stainless Steel SS316L Heating Plates

Brazing Materials

- Copper, Nickel, and Stainless

Maximum Working Pressure

- Up to 650 PSI (4.48 MPa)

Maximum Working Temperature

- Up to 445°F (230°C)

Compact models with high heat transfer capacity Stainless steel plates with corrugated surface ensure turbulent flow and structural support to the unit High heat transfer coefficient Cost efficiency Single or double wall option. Copper, nickel and stainless brazing material available Quick and easy installation

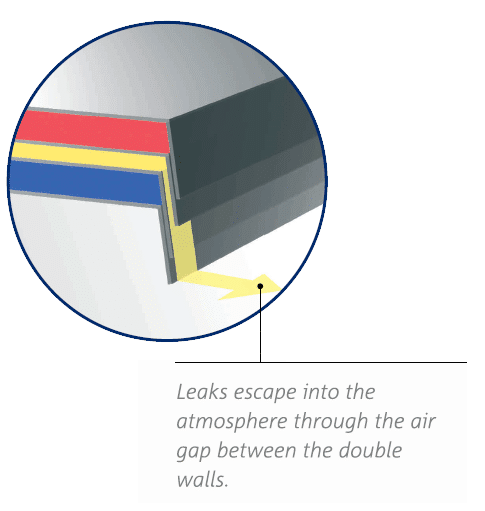

Two stainless steel plate walls separate the fluid streams, with an air gap in between. In the event of a leak, the affected fluid will flow into the air gap and escape out of the heat exchanger, enabling visual detection of the leak.

Advantages of Double Wall Brazed Plate Heat Exchangers

- Visual leak detection

- Reduces risk of fluid cross-contamination

- High thermal efficiency

- Compact design, small footprint