P-Line Sanitary Heat Exchangers

Pharmaceutical & Food Grade Heat Exchangers

Characteristics

- FDA, cGMP, ASME, and 3A requirements

- Stainless Steel 316 construction

- Double tubesheet construction

- Construction without dead spots, minimizing possibility of microbial growth

- Polished to Ra < 0.5um

- Certified seamless tubes polished internally and externally

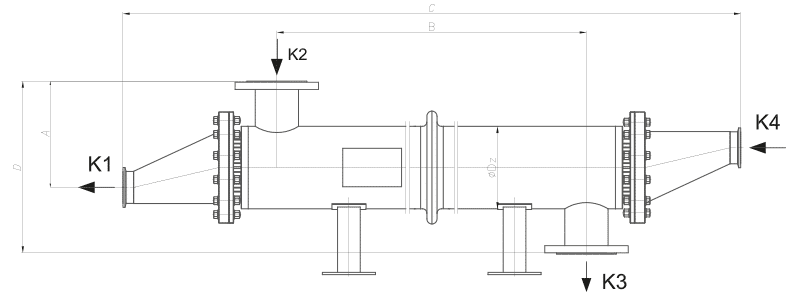

- One-, Two-, or Four-pass type interchangeable heads

- Vertical or horizontal mounts available

We offer products of the highest quality and reliability to satisfy our customers’ most rigorous demands.

Standard Materials

- Stainless steel 316L

Maximum Working Pressure

- Up to 145 PSI (10 bar) in Tubes

- Up to 232 PSI (16 bar) in Shell

Maximum Working Temperature

- Up to 284 °F (140°C) Tube Side (Viton Seal)

- Up to 250 °F (121°C) Tube Side (Silicon Seal)

- Up to 397 °F (203°C) Shell Side

Pharmaceutical and Sanitary Heat Exchangers

P-Line – a series of exchangers for pharmaceutical and food industries and suitable for all other applications that are in compliance with FDA and 3A.

The unique construction of P-Line series exchangers reduces the risk of cross-contamination of the media even in the case of unsealing of the tubesheet-tube connections; it also ensures correct operation in applications requiring the highest standards.

Applications

Food & dairy Industry:

- Juice and syrup handling

- Chocolate and high viscosity products handling

- Brewery

- Milk cooling

- Pasteurization

Pharmaceutical:

- Clean steam

- Blood, plasma or media growth heating systems

- Water for injection systems (WFI)

- Process equipment

Industries

- Pharmaceutical

- Biotech

- Food processing

- Beverage production

- Dairy

- Cosmetics / Fragrances

- Semiconductor

- High purity