M-Line Marine Alloy Heat Exchangers

M-Line heat exchangers are a line of completely welded heat exchangers made entirely of a super austenitic marine alloy. Its compact structure is an integration of innovative material with detailed engineering for effective use with high fluid velocities and low pressure drops, designed specifically for salt water pool applications.

The versatility of this robust straight tube design covers a comprehensive range of capacities, suitable for all residential and commercial pool applications.

Typical applications include

- Salt water pools, spas, hot tubs

- Transmission and engine coolers

- Marine Oil coolers

- Boiler sample coolers

- Waste water heat recovery

Standard Materials

- Nicrom 24 (super austenitic alloy)

Maximum Working Pressure

- Up to 150 PSI (1.03 MPa)

Maximum Working Temperature

- Up to 406 °F (208°C)

Combine engineering ingenuity with nature’s vitality, and yield a resilient, super austenitic marine alloy product series that has continuously demonstrated its superior performance and strength over other commercially marketed marine alloys. True to form, the M-Line is a marriage of resistances: superior corrosion resistance with high erosion corrosion resistance, highly valued for its use in seawater and salt water environments.

Distinct Advantages

- Superior corrosion resistance provides protection for salt water and other marine applications.

- High erosion corrosion resistance suitable for applications with high fluid velocities.

- High material strength for quality performance and long product life.

- Low pressure drops.

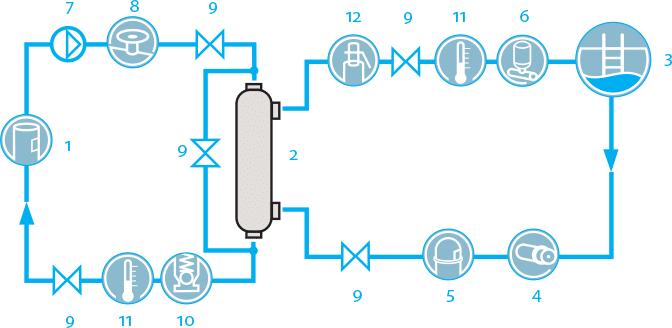

Typical Swimming Pool Installation

- Boiler

- Heat Exchanger

- Swimming Pool

- Pump

- Filtration

- Chlorine Feeder

- Circulation Pump

- Flow Control Valve

- Gate Valve

- Check Valve

- Thermometer

- Safety Relief Valve