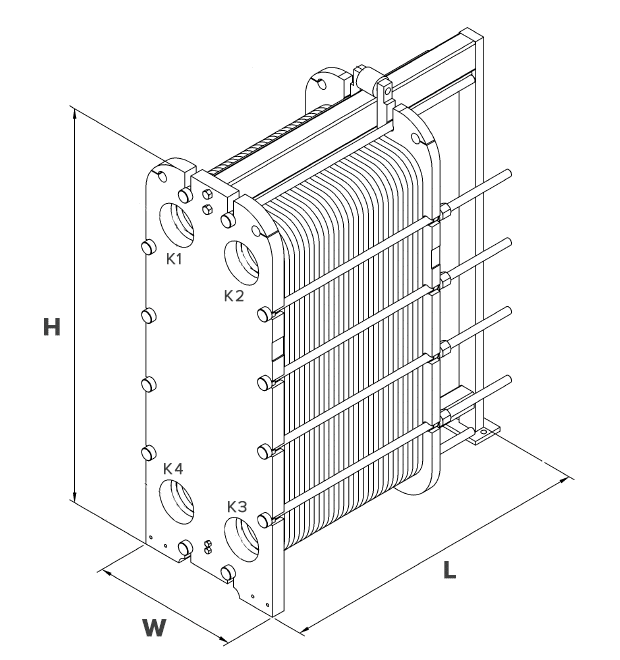

A-Line Heat Exchangers

Plate and Frame Heat Exchangers

AIC is pleased to introduce the latest plate and frame technology to the heat transfer marketplace.

At the heart of the efficient A-Line Heat Exchanger system are a series of models available in a variety of materials and plate designs. This provides our clients with a flexible, reliable, cost-effective means of achieving precision heat transfer. These advantages make the A-Line Heat Exchanger the ideal choice for chemical, pharmaceutical, HVAC and food industries.

We offer products of the highest quality and reliability to satisfy our customers’ most rigorous demands.

Applications

- Chemical Industry

- Pharmaceutical Industry

- HVAC Industry

- Food and Beverage Industry

- Marine Industry

- Automotive Industry

- District Energy

Standard Materials

- SS304/SS316/Titanium heating plates

- Carbon Steel Frame

- EPDM/NBR Gaskets

Standard Working Pressure

- Up to 450 PSI (3.1 MPa)

Standard Working Temperature

- Up to 350°F (176°C)

Plates & Gaskets

- Plates with an extensive range of heat transfer areas

- Varying plate thickness

- Plate materials: SS 304, SS 316, Titanium, Hastelloy

- Glued or Clipped on gaskets

- Gasket materials: EPDM, NBR, VITON